Caption:

A NAO robot developed by Aldebaran Robotics dances to a song at

the World Robot Conference in Beijing on November 24/ JASON

LEE/REUTERS

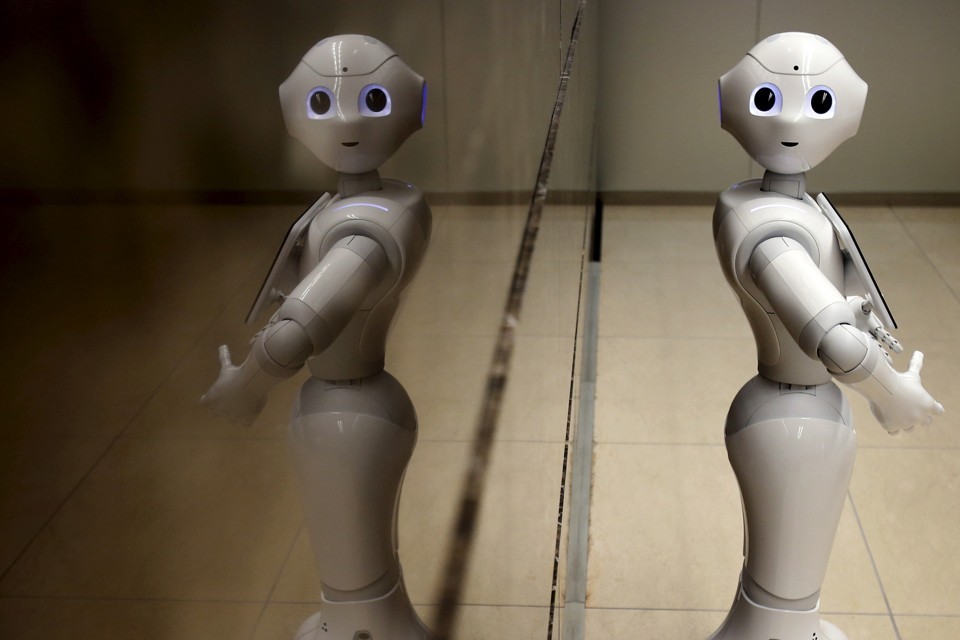

Caption:

SoftBank’s human-like robot, Pepper, welcomes customers to a

bank in Tokyo, in 2015/ Yuya Shino / Reuters

Artificial Skin to Provide Robots with Sense of Touch

San Francisco, London- Robots can finally feel hot and cold through their sense of touch after researchers from the University of Houston have reported a breakthrough in stretchable electronics that can serve as an artificial skin. Cunjiang Yu, Bill D. Cook, assistant...Caption:

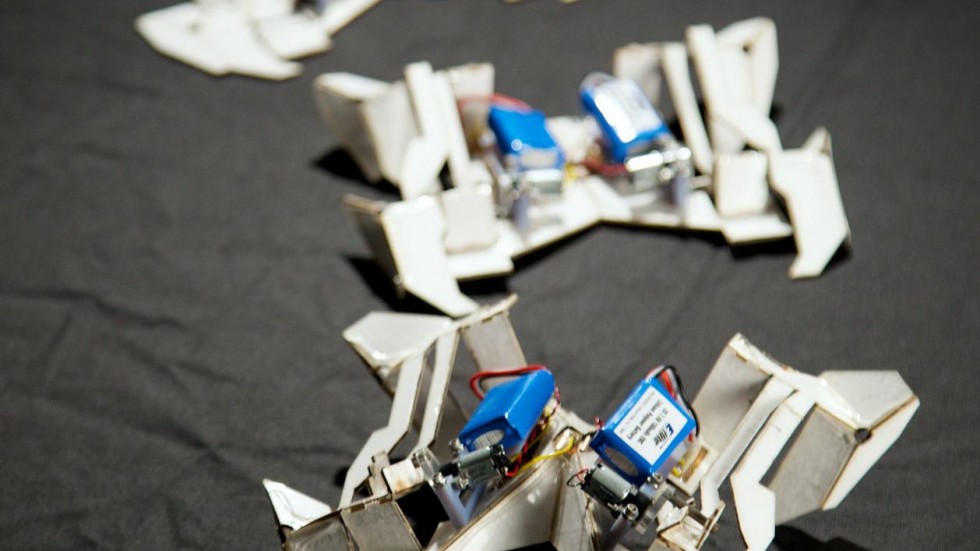

Self-folding robots that have been inspired by the Japanese art form of origami. (AFP)

US Researchers Develop Battery-Less Foldable Robots

San Francisco, London – A team of US researchers has reached a new technique to develop foldable robots based on the Japanese paper folding art known as “origami”. The manufacture of traditional robots generally requires onboard batteries or a wired connection...Caption:

Two CTR robots play Chinese ancient chime bells at the World Robot Exhibition during the World Robot Conference in Beijing, China, November 24, 2015. The conference, which kicked off in Beijing on Monday, is a three-day event including a forum, an exhibition and a robot contest for youths, Xinhua News Agency reported. REUTERS/Jason Lee

Switzerland Unveils First Digital Building

Cologne, Germany- The Swiss “Hoho Tower” has been listed in Guinness records as the first 84m, 24-story twin tower project built only from wood. Following this success in the field of eco-friendly construction, Swiss engineers will soon start a new adventure to build...Caption:

Kiva robots move racks of merchandise at an Amazon fulfillment center in Tracy, Calif., where there are two robots for every human worker. Policy makers can help prepare people for a time when more jobs are automated. Credit Justin Sullivan/Getty Images